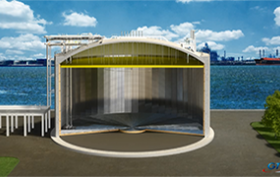

GST®, the membrane Full Integrity System for LNG Land Storage Tanks

The storage of liquefied natural gas makes it possible to ensure an uninterrupted supply and to respond to peaks in energy consumption.

GTT has developed GST® technology, based on Mark III technology, which has proven its reliability and robustness over 60 years of existence. It is a safe and adaptable solution, whatever the tank capacity. It complies fully with international standards and meets the highest safety standards.

Tried and tested for over 50 years for the oldest ones, more than 40 onshore tanks are currently in operation.

Separation of the main functions

The GST® concept is based on a clear separation of the 3 main functions required from a land storage tank; tightness, thermal insulation and structural resistance.

The GST® concept is based on a clear separation of the 3 main functions required from a land storage tank; tightness, thermal insulation and structural resistance.

- Tightness is provided through the membrane

- Thermal insulation through the insulating panels

- Structural resistance through the concrete or low temperature steel walls (designed for inner and outer loads)

Prefabricated modular elements

The GST® technology consists of a combination of a limited number of modular basic shaped components.

The elements composing the membrane sheet layer as well as the insulating panels (typically 1m x 3m) are prefabricated in qualified supplier’s premises and fitted together on site.

GST® technology

- Primary Barrier

The primary barrier is made of a thin corrugated stainless steel membrane.The double network of corrugations absorbs the thermal contractions resulting from the very low temperature of the LNG and provide the liquid tightness as well as wall & bottom gas tightness

- Insulating panel

The thickness of the panels can be adjusted to provide a large range of boil-off rates according to the operator’s requirements (typically 0.05% per day for LNG).

The outer container provides the structural resistance to internal and external loads. A moisture barrier*, applied on its inner side, prevents moisture from entering the tank.

- Thermal Protection System (TPS)*

On the bottom and up to 5m: a composite laminated material is integrated in the panels.

This consists of a thin sheet of aluminium between two layers of glass cloth and resin. In the event of a failure of the primary membrane, it prevents the build-up of stress concentrations on the concrete corner and ensures the liquid tightness of the concrete wall, as required by standards.

Security

• Comprehensive containment solution

• Proven experience

• Certification from major inspection companies

• Insulation space under inert gas and permanently monitored

• Thermal protection of the bottom/wall junction for a high level of security*

Capacity

• No capacity limitation

• Much more net volume for a given dimension

• Possibility to integrate a sump in order to reduce the impumpables

Ease of supply

• Limited weight of stainless steel

• Economies of scale : same supply chain as the LNG tanker industry with membrane tanks

• Fast production of prefabricated elements

Ease of design

• 95% of elements are standard

• Well-suited for highly seismic areas

• Boil-off rate tailored to customer specifications

• Same design model, regardless of capacity

Ease of construction

• High percentage of prefabricated elements

• 85% of welds performed automatically (TIG procedure without filler metal, only one welding pass)

• Reduced construction schedule

Ease of Operation and Maintenance

• Almost no restrictions on the rate of cooldown

• Quick Shutdown if necessary

• No maintenance required

Competitiveness

• Standard, non exclusive license agreement with EPC, allowing for free competition

Carbon Footprint

• Reduced carbon footprint by up to 16%

• Supports the use of local labor

* Only in case of concrete outer tank