LNG Brick: the package for gas storage dedicated to propulsion

The latest regulations adopted by the International Maritime Organization (IMO) will constrain merchant vessels’ ship-owners to comply with lower Sulphur oxide emissions rates by 2020. The use of Liquified Natural Gas (LNG) is a real technological breakthrough to reach compliance and maintain competitiveness at the same time.

As a response to this requirement, GTT has developed the LNG Brick® technology.

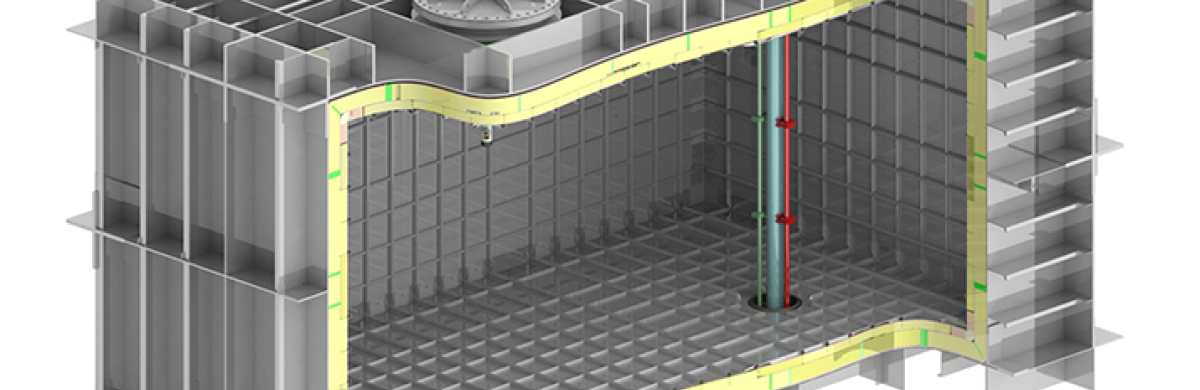

LNG Brick® is a package for storage of gas for propulsion dedicated to ships requiring a small quantity of LNG (less than 3.000 m³). It includes storage and the gas preparation room. LNG Brick® is delivered as a block ready to be integrated into the ship structure.

The LNG Brick® technology is mainly dedicated to vessels with high cargo/cabin constraints where its cubic geometry applies such as for ferries, car carriers, and container vessels.

Any shipyard can consider the solution as there is no requirement for a particular knowledge on membrane or LNG tanks since the tank is delivered already outfitted and tested.

The cubic shape is designed to suit the space available, thereby offering a more space-efficient solution than other technologies. For instance, compared to independent type C tanks, it is possible to load 50 to 100% extra LNG fuel in the same given space. It means that the vessel autonomy can be significantly increased.

The operational flexibility has been increased, thanks to its ability to maintain a higher pressure than traditional membrane tanks. It ensures more than 15 days of holding time (tank closed).

Components are standardized to limit the number of references. It simplifies the design and makes LNG Brick® more competitive.

LNG Brick® is delivered as a block ready to be integrated into the ship structure, suitable for tank sizes from 300 to 3,000 m3.

It incorporates the proven Mark III membrane system which has been simplified and standardized for a small cubic tank.

Membrane is outfitted in a self-supported tank and then integrated by the yard to the vessel.

GTT has demonstrated the feasibility with class societies and has now been endorsed by approvals in principle from DNV, ABS, LR, and BV. Moreover, on December 2017, a pressure test under cryogenic conditions was performed on the LNG Brick® prototype, demonstrating the full membrane ability to sustain an increased vapour pressure.