GTT has recently developed a reduced combined dome dedicated to LNG fuelled ships fitted with Mark III tanks, taking advantage of the less challenging requirements in terms of space, for this kind of vessels compared to LNGCs. This dome and the related pump tower of reduced dimensions offer more flexibility in tank design and containment system installation as well as a cost reduction.

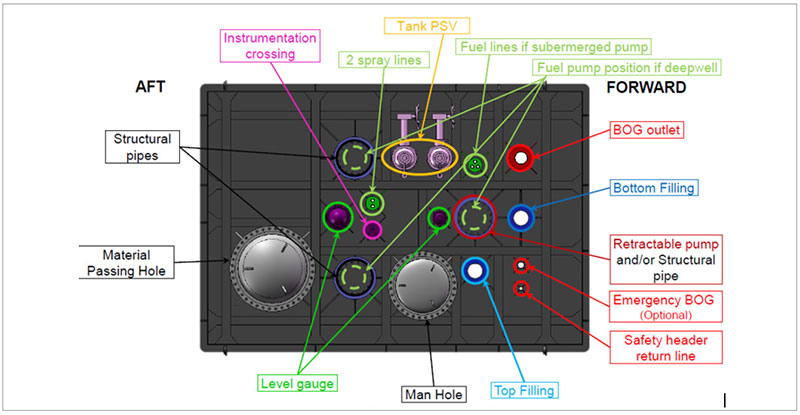

The domes are critical parts of an LNG tank, as they contain most of the pipes crossing the containment system while maintaining the insulating and tightness. The liquid dome is also supporting the pump tower (PT) on which the pumps are attached in order to load and

discharge the LNG. Many other key components are installed on the domes such as the tank Pressure Safety Valves, the level gauges, the material passing hole and the manhole.

In the specific case of LNG fuelled ships (LFS), the LNG fuel tank has smaller dimensions than LNG carrier tanks and liquid and gaseous lines are of smaller diameter. This permits a combination of the usual gas dome and liquid dome of a LNGC into one single rectangular combined dome for LFS applications.

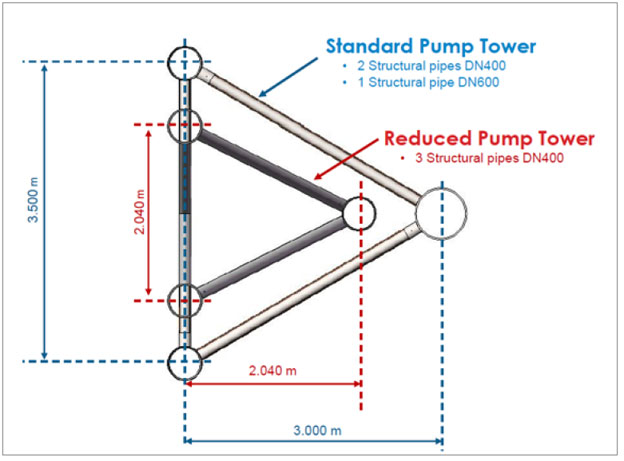

Figure 1: Size reduction of pump tower

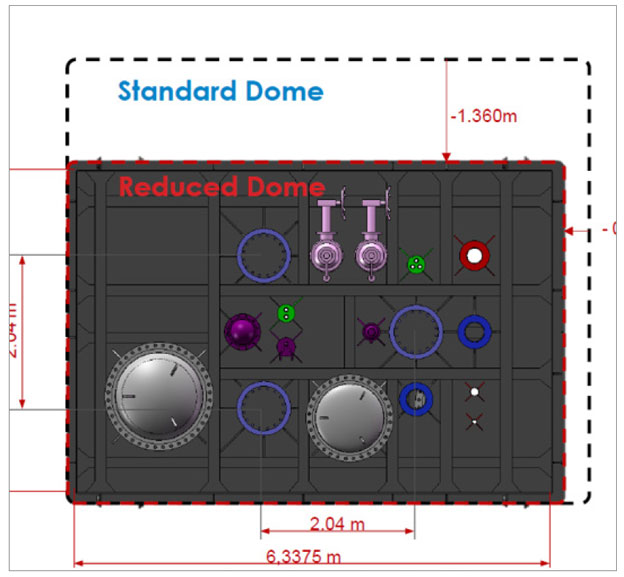

Going further into this optimisation process for LFS, GTT has then worked on an optimised design for the pump tower and for the combined dome. The structural pipe diameter in the forward position of the PT has been changed from DN600 to DN400. The PT footprint has been reduced from 3.5m x 3m down to 2.04m x 2.04m as displayed on Figure 1. This major improvement reduces the size of the combined dome (Figure 2): -10.6m2 less surface occupation.

Figure 2: Size reduction of rectangular combined dome

This Reduced Rectangular Combined Dome (RRCD) has been validated by extensive numerical studies, which concluded that it can be used even for large LFS tanks of Ultra Large Container Vessels (23,000 TEUs). The application range of the RRCD for Mark III LNG fuelled ships extends from tankers and bulkers to all sizes of container vessels. The main features of the standard dome remain available for this new RRCD: ship-owners and shipyards keep the flexibility to choose between deepwell pumps and submerged pumps and to apply a sump well in order to minimise the LNG heel level (Figure 3).

Figure 3: Overview of pipes crossing the RRCD

Applying the RRCD brings several significant advantages:

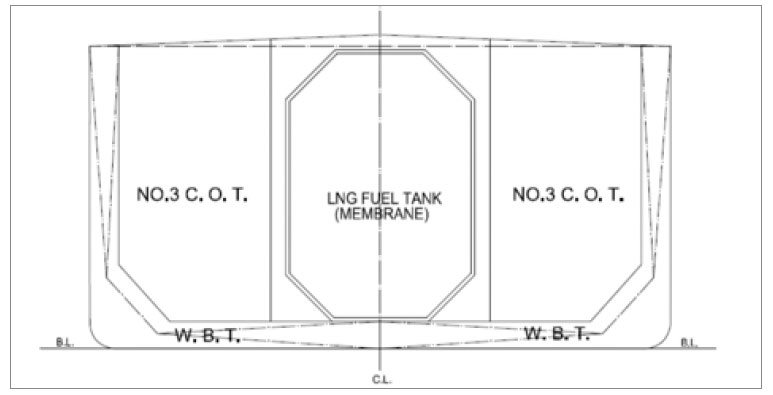

- Limited footprint makes it particularly interesting for narrow tanks. In case of Very Large Crude Carriers (VLCCs) for instance, the Mark III LNG fuel tank can be fitted in the cargo area, between the two internal longitudinal bulkheads (Figure 4). The reduced width of the new dome fits then perfectly with the narrow ceiling.

- Reducing the size of the dome and of the PT obviously comes with savings on raw materials, with around 10T of stainless steel saved1.

- It provides more flexibility at construction stage, giving more space for scaffolding inside the tank for installing the containment system.

Material passing hole and manhole are fitted with standard circular flanges. The upgrade for increased maximum pressure to 1 barg (instead of typical 700 mbarg as stated by IGF Code2) is then simplified and is currently under study.

The Reduced Rectangular Combined Dome should become the standard dome for the Mark III LNG fuel tank, reducing the cost of the fuel tank and easing its construction.

1 Best estimate based on standard project configuration.

2 More details on increased maximum pressure for Mark III LNG fuel tank can be found in our dedicated webinar: WEBINAR SUBSCRIPTION CENTER & ON-DEMAND REPLAY | GTT.