Boil-off gas is a key parameter in LNG Carrier design and operations. It is directly related to the economics of the LNG transportation industry. Traditionally, we divide boil-off gas into two components, static and dynamic. The first depends on the ship design and the performance of the insulation system. The second includes all the other factors that are variable during the operations such as the environmental parameters or the navigational decisions. Once the ship is designed, there is little margin to improve the static boil-off. However, the margin to improve the dynamic boil-off is significant.

Every LNGC operator has its own strategies and benchmarks to manage the boil-off. In addition, the way they monitor it is different depending on many factors like the maturity of the company, the awareness of the crew, the charter party conditions, etc.

GTT has studied the boil-off management of many ships in operation for a number of years. This confirmed that the operator metrics and strategies are indeed different. It also showed that some metrics and strategies lead to counterproductive “singularities” especially when the focus is exclusively on the Gas Combustion Unit and not on the overall consumption.

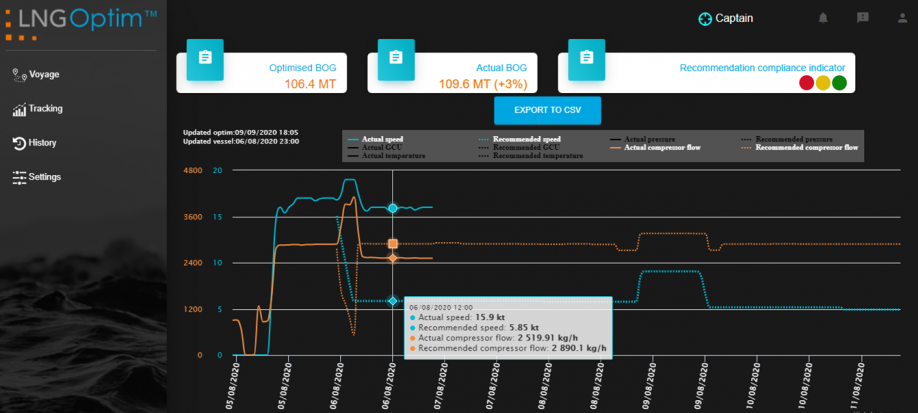

Based on its unique expertise, GTT has developed advanced algorithms to predict the LNG consumption during LNGC voyages. This includes the modelling of complex phenomena such as LNG ageing and the influence of sea states on Boil-off gas generation, in addition to the impact of active systems like reliquefaction plants and subcoolers.

LNG Optim helps plan the voyages in advance in order to reduce the overall consumption. If there is any changes in the voyage plan during the sea passage, the systems updates the recommendations accordingly.

LNG Optim is already deployed on many LNG carriers, old and recent. Old vessels use the system to improve the operational economics and reduce the emissions. In fact, with the environmental regulation becoming more and more stringing (e.g. EEXI), managing emissions is becoming a hot topic. For the new vessels with active Boil-off gas management equipment, GCU usage is rare in theory. This is no longer a relevant KPI for good energy management. Thus, LNG Optim makes sure the combined systems are used at the optimum level to avoid unsuspected over-consumption.

Captain Guy Nicholls, Director Marine Operations of Cheniere Energy, said: “Collaborating with the GTT LNG Optim program will assist with achieving our goals to continuously improve operational performance and decision making for our globally-traded fleet and provide potential opportunities to further understand and reduce emissions.”

LNG Optim is part of the GTT Digital Platform that offers other unrivalled smart shipping products for ship owners, charterers and operators.