GTT MARS, the technology for LPG vessels

GTT MARSTM is the result of GTT’s proven expertise in the field of liquefied gas containment systems for maritime transport and onshore storage. It relies on an unrivalled experience from over 300 LNG carriers around the world. Classical GTT membrane containment systems, designed for LNG transportation, have already carried LPG in the past, and are used for LPG storage on offshore platforms.

GTT MARSTM is designed for the specific application of LPG transport. It is suited for a cargo temperature range from -55 °C to 0 °C.

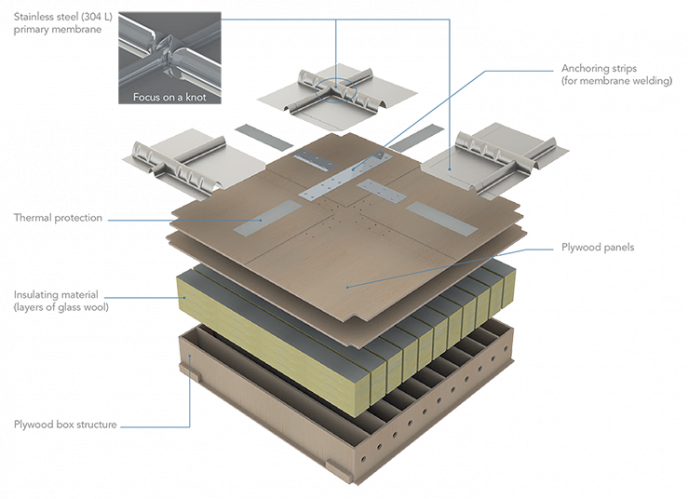

The solution is based on a single membrane concept. The insulation is fitted on the inner hull of the vessel, which acts as the secondary barrier of the tank, and supports the primary barrier.

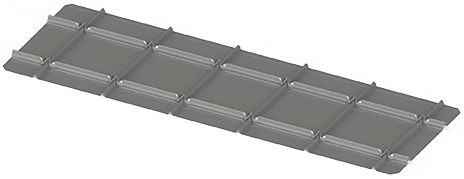

This primary barrier is made of corrugated stainless steel.

GTT MARS (TM) CCS Design

Optimised storage space

As the containment system follows the contours of the hull, GTT MARSTM makes it possible to both carry more LPG than self-supporting solutions and reduces the weight of the vessel. The solution adapts to any shape and size of vessel.

Safety and reliability

The primary barrier, which is in contact with the cargo, has corrugations. The corrugation knots, located at each intersection, are designed to be able to fully unfold during an external event.

GTT primary membrane

GTT considers the construction risks when determining the design of the membrane technology.

Simplified cargo operations

- Twice as less energy, and therefore LPG, needed to cool down the tank

- Operation times are significantly reduced: 3-4 hours with GTT membrane technology compared to 20 hours for a self-supporting tank

- Loading possible without cooling the tank in advance

- Reduced ship detention time