LNG carriers have to meet the terminal requirements in order to be allowed to unload the cargo. The requirements define acceptable ranges for different parameters like LNG composition, Gross Heating Value, Wobbe Number, LNG density, Saturated Vapour Pressure, Temperature…

During the laden journey, new commercial instructions might be received leading to a change in the time of arrival and/or the discharge port. When this happens, the LNG cargo may be in unacceptable condition for the new discharge terminal.

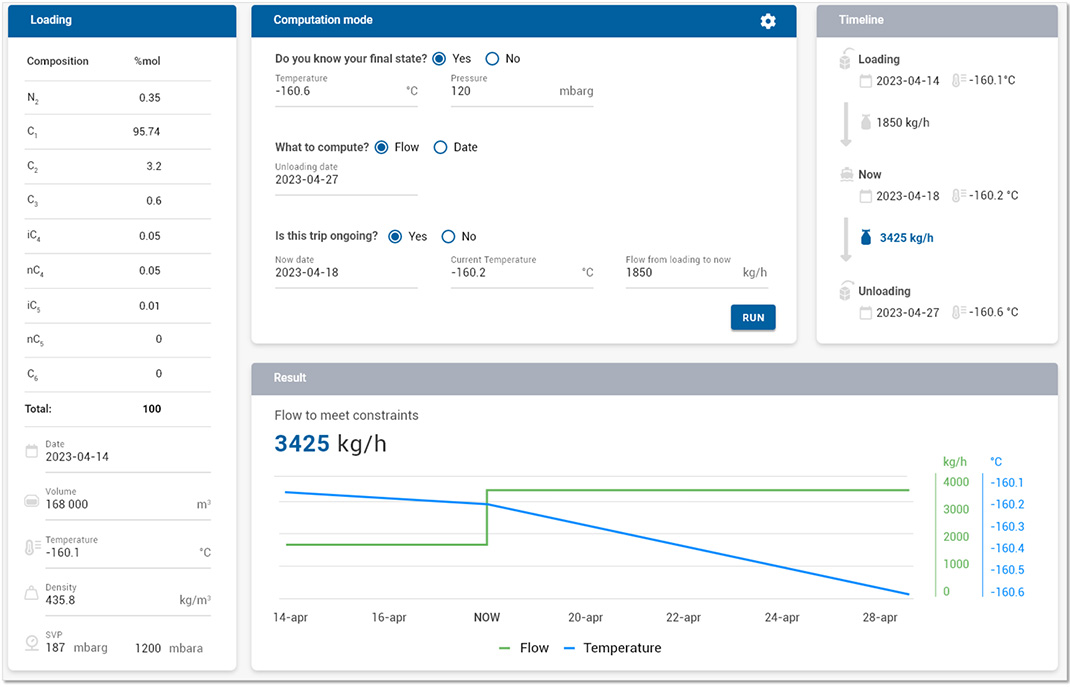

GTT has developed a new module for cargo conditioning for LNG carriers based on GTT’s expertise in the LNG process and experience in helping captains deal with these situations. The tool calculates from expected unloading condition (e.g. LNG temperature/ saturated vapour pressure), the amount of LNG that requires to be evaporated, minimizing the cargo loss and thus the emissions. Once the Boil-off-Gas (BOG) flow is required to is known, the cargo can be recondition to satisfy the charterer’s request.

The section “Loading” contains the cargo loading date, volume and thermodynamic properties. The section “Computation mode” is used to configure the prediction model (unloading conditions, desired output and voyage constraints). The section “Results” displays the simulation outcome (the BOG flow to be extracted from the tanks and the summary of the expected cargo loss by consumer).

Use case:

|

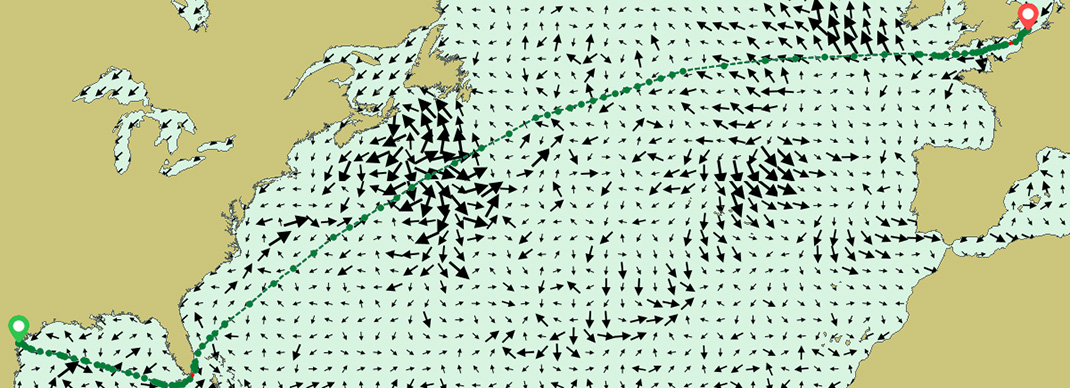

Route |

USCRP è FRDKK |

|

Distance (nm) |

5027 (constant in this use case) |

|

Volume_i (cbm) |

171 340 |

|

Loading temp (°C) |

-160.2 |

|

LNG comp (%mol) |

C1 : 96.4 / N2 : 0.04 |

Four different speed profiles are explored:

|

Unit |

Slow |

Mid-speed |

High speed |

Very high speed |

|

|

Avg. Speed |

kn |

11.5 |

14.1 |

16.2 |

18.6 |

|

ETD |

14/12/2022 00:00 |

14/12/2022 00:00 |

14/12/2022 00:00 |

14/12/2022 00:00 |

|

|

ETA |

01/01/2023 04:26 |

28/12/2022 21:21 |

26/12/2022 22:46 |

25/12/2022 05:59 |

|

|

Duration |

d |

18.2 |

14.9 |

12.9 |

11.2 |

|

Speed_actual |

kn |

11.5 |

14.1 |

16.2 |

18.6 |

|

ME |

MT |

282.8 |

442.61 |

504.98 |

665 |

|

DG |

MT |

207.3 |

169.7 |

147.6 |

128.2 |

|

Total conso |

MT |

490.1 |

612.4 |

652.6 |

793.2 |

|

Distance |

nm |

5027 |

5027 |

5027 |

5027 |

Each speed profile is studied according to cargo conditioning to meet different unloading temperatures (considered within the terminal acceptable range):

- -159.4 °C

- -159.6 °C

- -159.8 °C

- -160.0 °C

- -160.2 °C

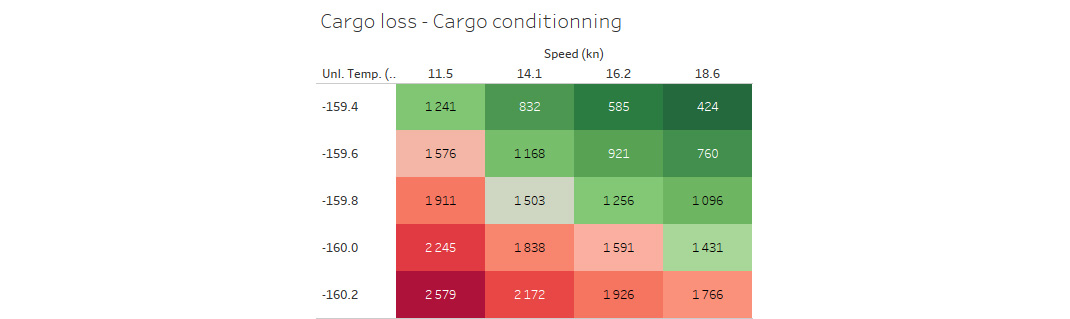

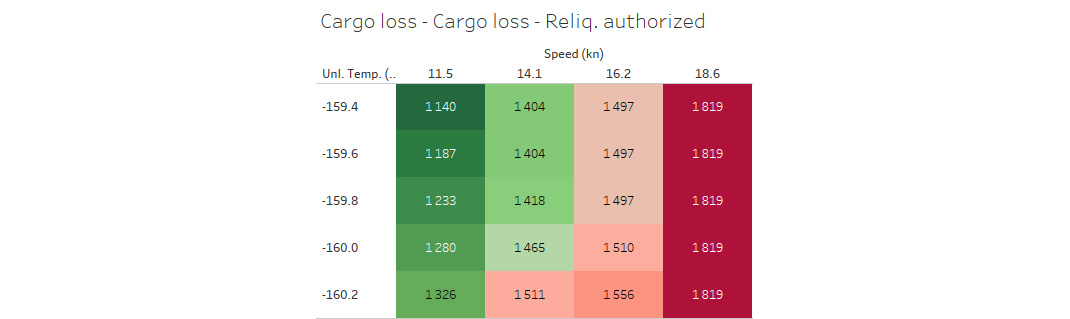

Result: Cargo loss expected based on discharge constraints

The charts below show the total cargo lost for a given laden speed (from the table above) and a given unloading temperature.

- Reliquefaction plant OFF

When the reliquefaction plan is off, Cargo Loss is indicated below.

- Reliquefaction plant ON

When the reliquefaction plan is on, Cargo Loss is indicated below.

Result analysis

Of course, the flexibility of the unloading time and temperature is subject to commercial considerations. Moreover, the sensitivity analysis can be pushed further by taking into consideration other parameters like the distance (route).

However, the use case shows that the variation of key parameters can result in big difference in cargo loss:

- In the first scenario (reliq OFF), the difference between the two extremes is (2579 – 424) = 2155 cbm = 482 720 USD*

- In the first scenario (reliq ON), the difference between the two extremes is (1819 – 1140) = 578 cbm = 152 096 USD*

The Cargo Conditioning module helps the operator assess the cargo loss beforehand and defines the correct parameters (unloading temperature, speed…) to minimize it.

* : market assumption: 10 USD/MMBtu